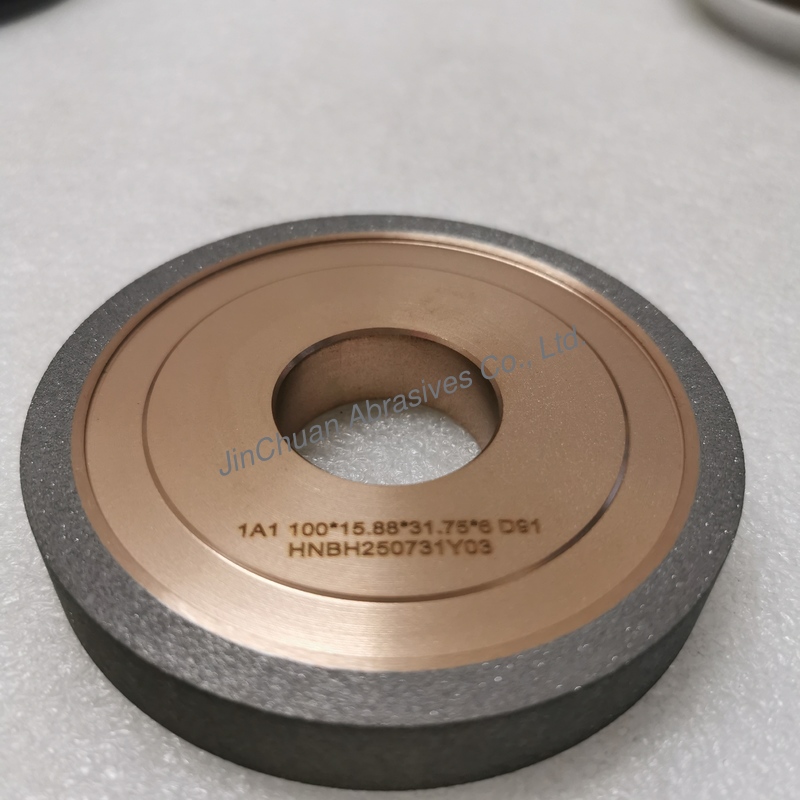

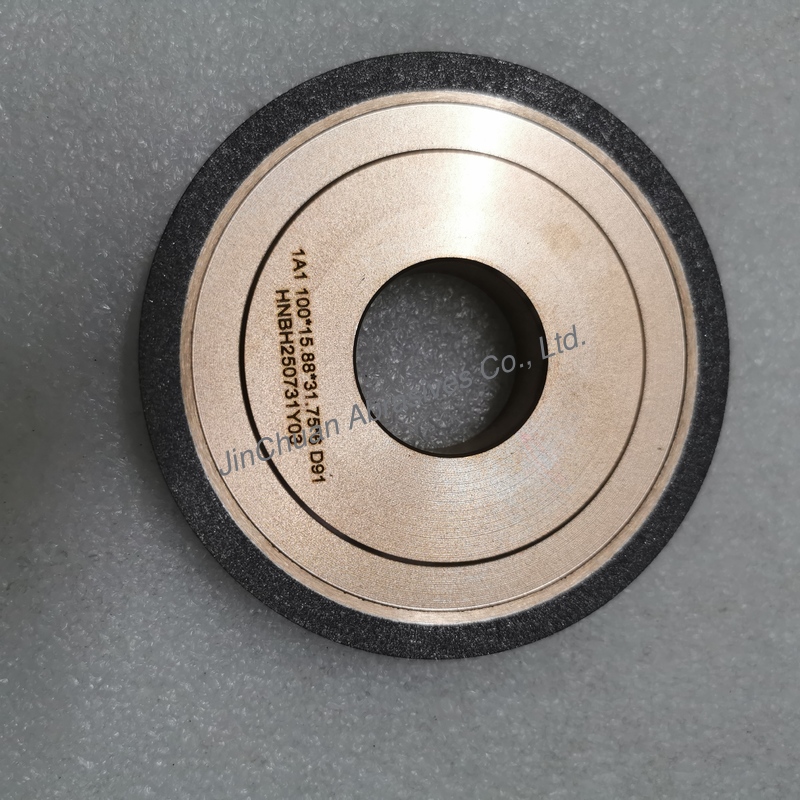

Resin And Metal Hybrid Bond Hybrid 1A1 100*15.88*31.75*6mm D91 Diamond Grinding Wheel Higher Efficiency Longer Life

-

Resaltar

Diamond grinding wheel with resin metal hybrid

,100mm diamond grinding wheel D91

,High efficiency diamond grinding wheel

-

Espesor15.88m m

-

Cuerpo de baseResina y enlace de metal

-

Tamaño de arenaD91

-

PaqueteEnvasado de exportación

-

PerfilMolienda de alta precisión

-

Lugar de origenPORCELANA

-

Nombre de la marcaJC

-

CertificaciónISO

-

Número de modelo1A1

-

Cantidad de orden mínima2 piezas

-

PrecioNegociable

-

Detalles de empaquetadouno en una caja de papel

-

Tiempo de entrega7 días

-

Condiciones de pagoTT, Western Union, PayPal

-

Capacidad de la fuente10000/mes

Resin And Metal Hybrid Bond Hybrid 1A1 100*15.88*31.75*6mm D91 Diamond Grinding Wheel Higher Efficiency Longer Life

Product Description:

Hybrid grinding wheels are a combination of resin and metal, offering enhanced grinding and retention properties. They are currently widely used for batch processing of carbide and high-speed steel tools.

The key to Hybrit technology lies in its unique “Hybrid Bond” system. While conventional grinding wheels typically use a single type of bond (such as resin, metal, or ceramic), Hybrit technology intelligently combines different bond systems to achieve the best of both worlds.

Hybrid Bond System: Usually a metal + resin hybrid bond, it provides exceptional structural strength and stability, ensuring the wheel maintains its shape during high-speed grinding, resisting wear and extending its life.

This hybrid structure enables efficient grinding of hard and brittle materials (such as carbide, ceramics, glass, and tungsten carbide), as well as challenging steels (such as high-speed steel, tool steel, and stainless steel) and some metal composites. Its excellent chip evacuation and cooling properties reduce friction during grinding, resulting in less grinding heat and helping to prevent workpiece burns, microcracks, and metallographic changes. It is particularly well-suited for precision and ultra-precision machining.

Due to its high durability and low wear rate, Hybrit grinding wheels offer a very high grinding ratio, meaning they remove a significant amount of workpiece material before wearing very little, significantly extending wheel life and reducing unit cost.

Combining the advantages of both resin and metal bonds, it offers higher efficiency, longer life, and improved shape retention.

Features:

- Mixed bond

- Widely applicable

- High grinding ratio

- High grinding ratio

- Willfulness and flexibility

- Very long lifespan

- Very good self-sharpening

- Excellent surface quality

Technical Parameters:

| Material | Diamond |

| Package | cardboard box |

| Thickness | 15.88mm |

| Base Body | Resin + Metal Bond |

| Profile | High-quality grinding |

| Grit Size | D91 |

| Country Of Origin | China |

| Packing | Standard Exported Carton Packing |

| Hs Code | 6804211000 |

| Application | High-end precision manufacturing |

Applications:

Hybrit diamond grinding wheels, due to their superior performance, are widely used in applications requiring high precision, high efficiency, and long life:

Carbide tool grinding: Sharpening and flute grinding of milling cutters, drills, reamers, and taps.

Aerospace and automotive industries: Grinding precision components made of high-temperature alloys and composite materials, such as engine parts, turbine blades, and fuel injectors.

Cutting tool manufacturing: Essential tools for manufacturing PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride) tools.

Precision component machining: Precision grinding of carbide or ceramic parts, such as bearings, guide rails, and seal rings.

Semiconductor and optical industries: Machining of sapphire substrates, silicon crystals, and optical glass.

If you have specific processing requirements, please contact us directly. We can provide the most suitable Hybrit product model and processing parameter recommendations.